Michigan’s Leader in Testing Fixtures

15+ Years of Manufacturing

At DME Fabrication, we provide complete, start-to-finish test fixture solutions, from concept to final assembly, designed to meet the rigorous demands of automotive and industrial applications.

OUR solutions

CMM Dimensional Verification & Reverse Engineering

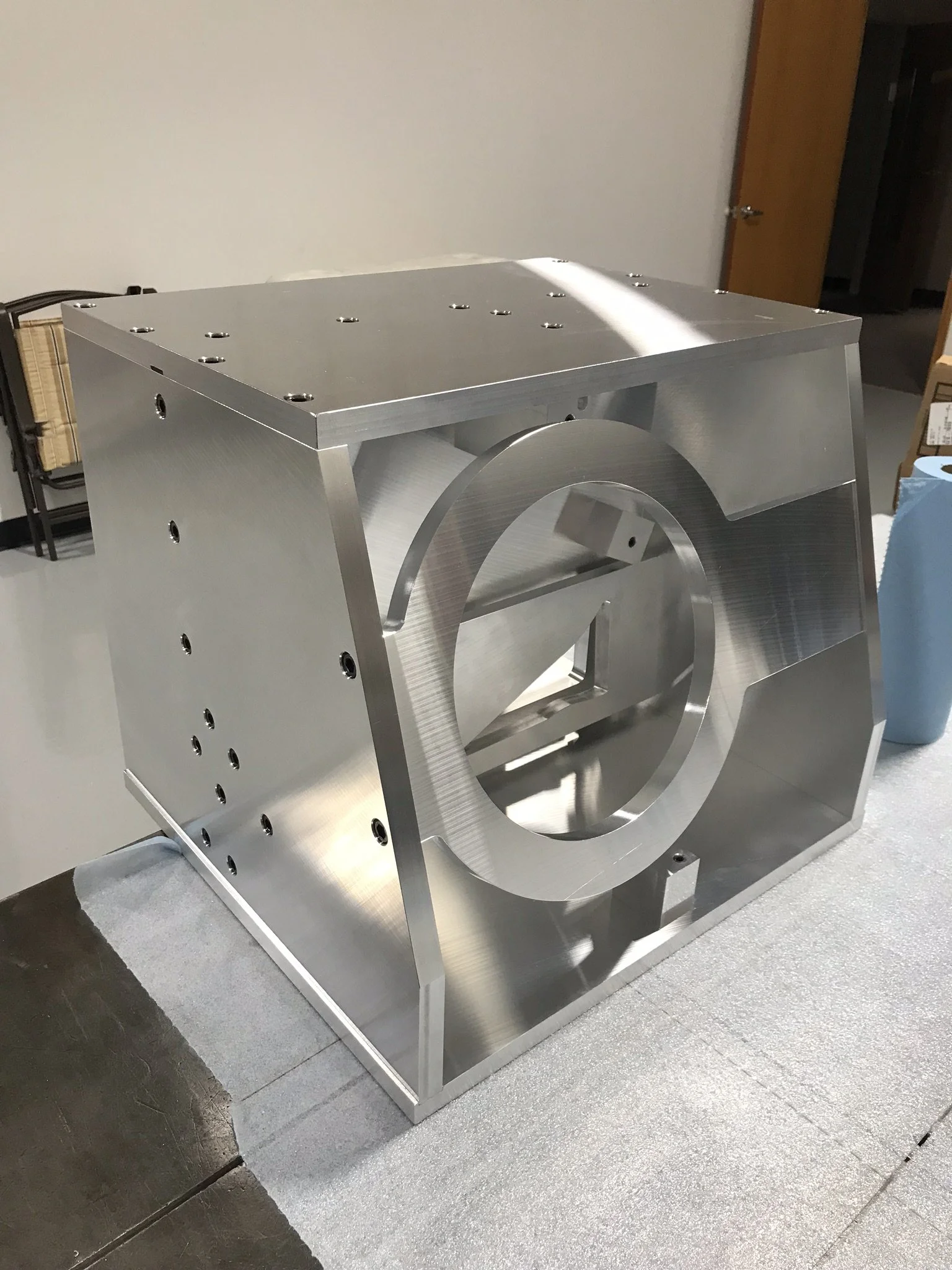

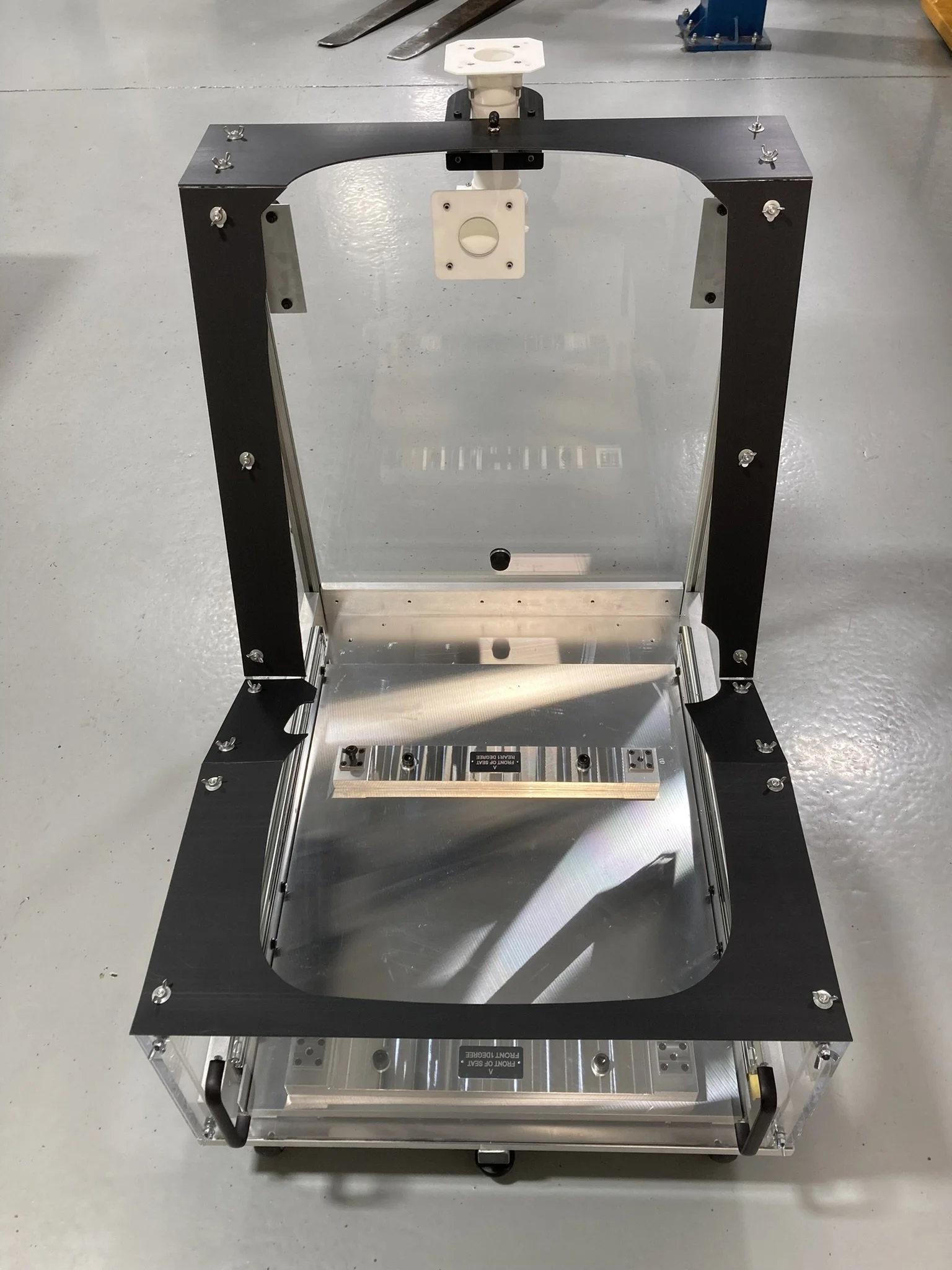

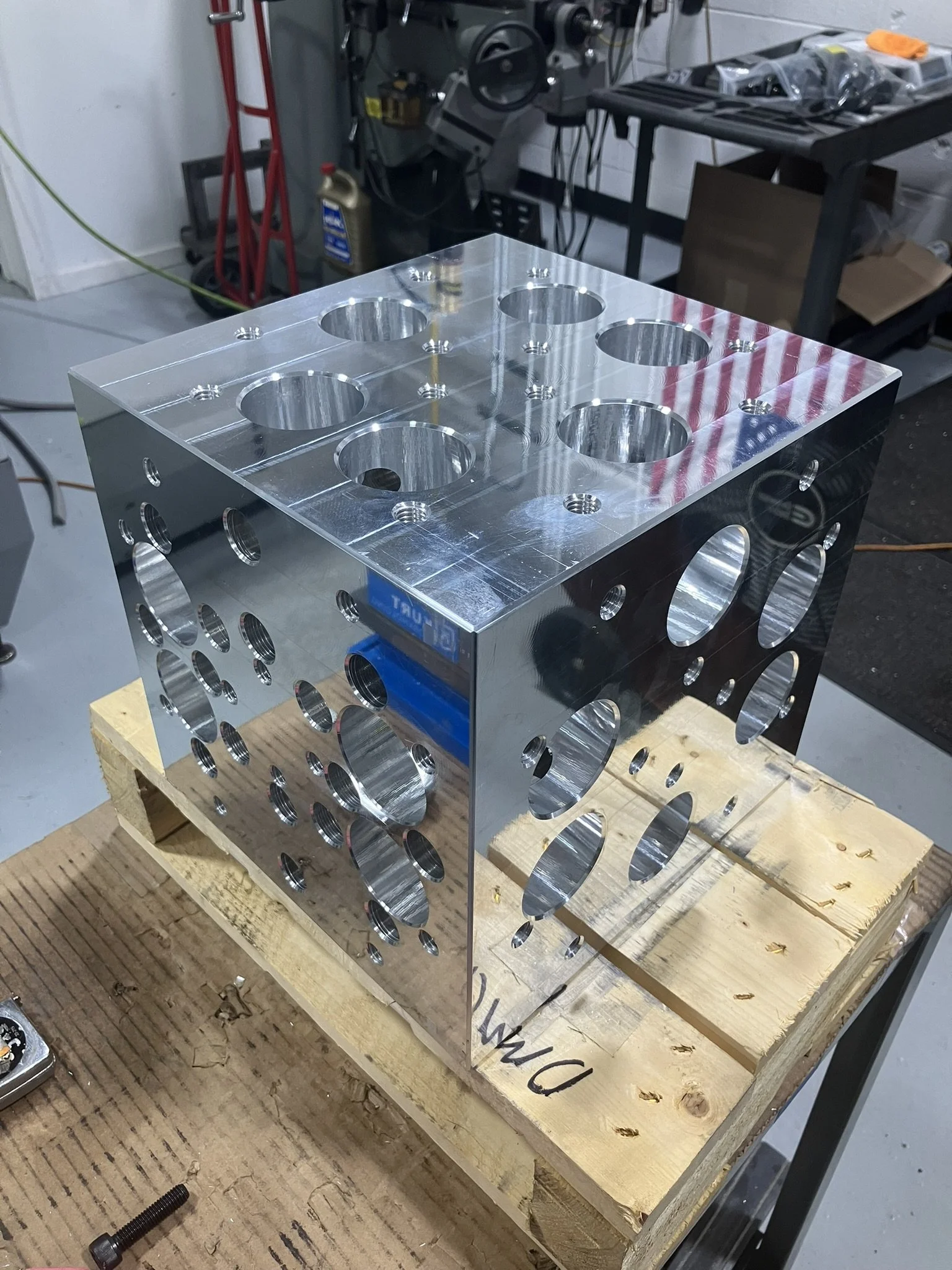

CNC Machining (3, 4, 5-Axis)

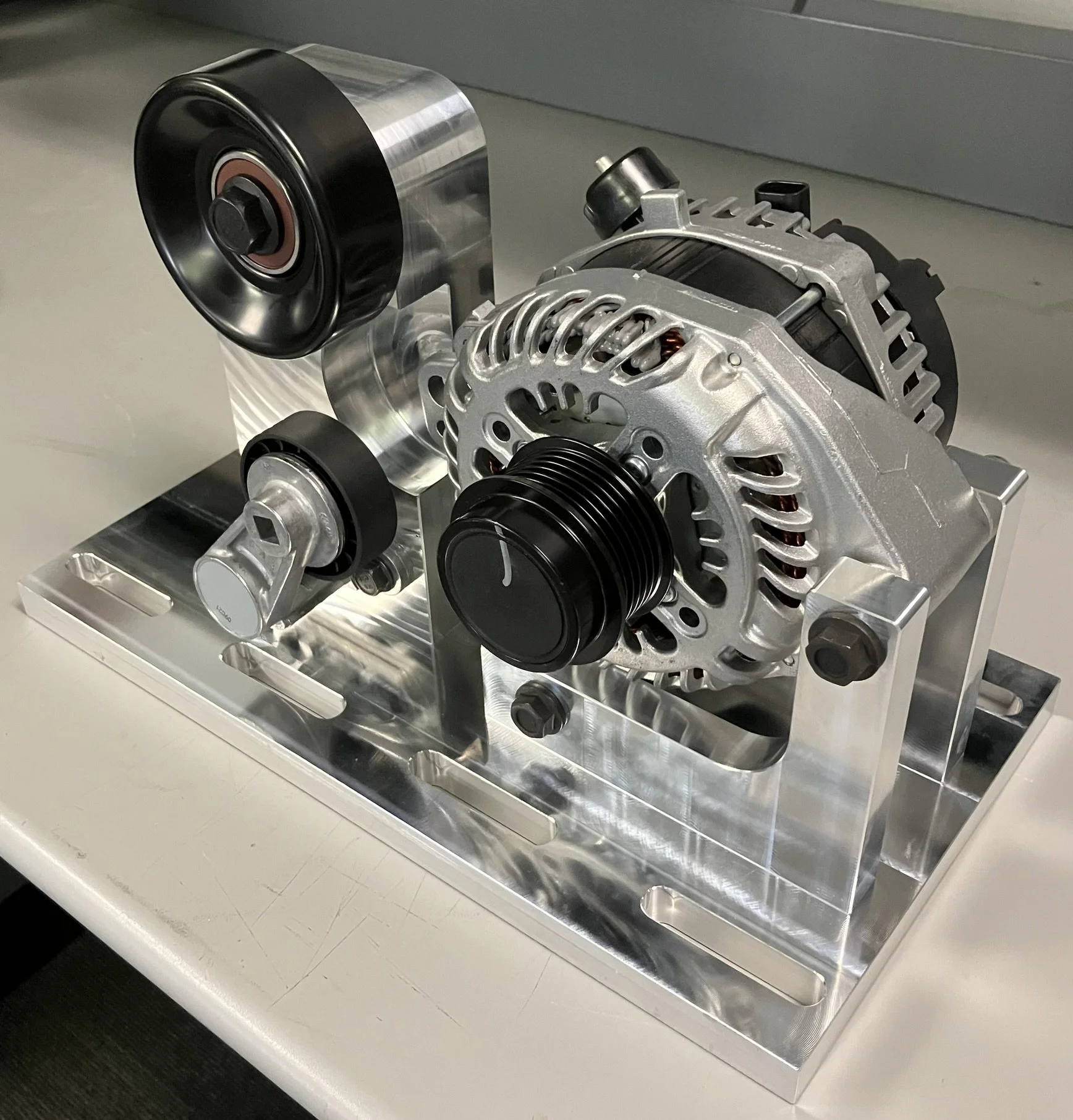

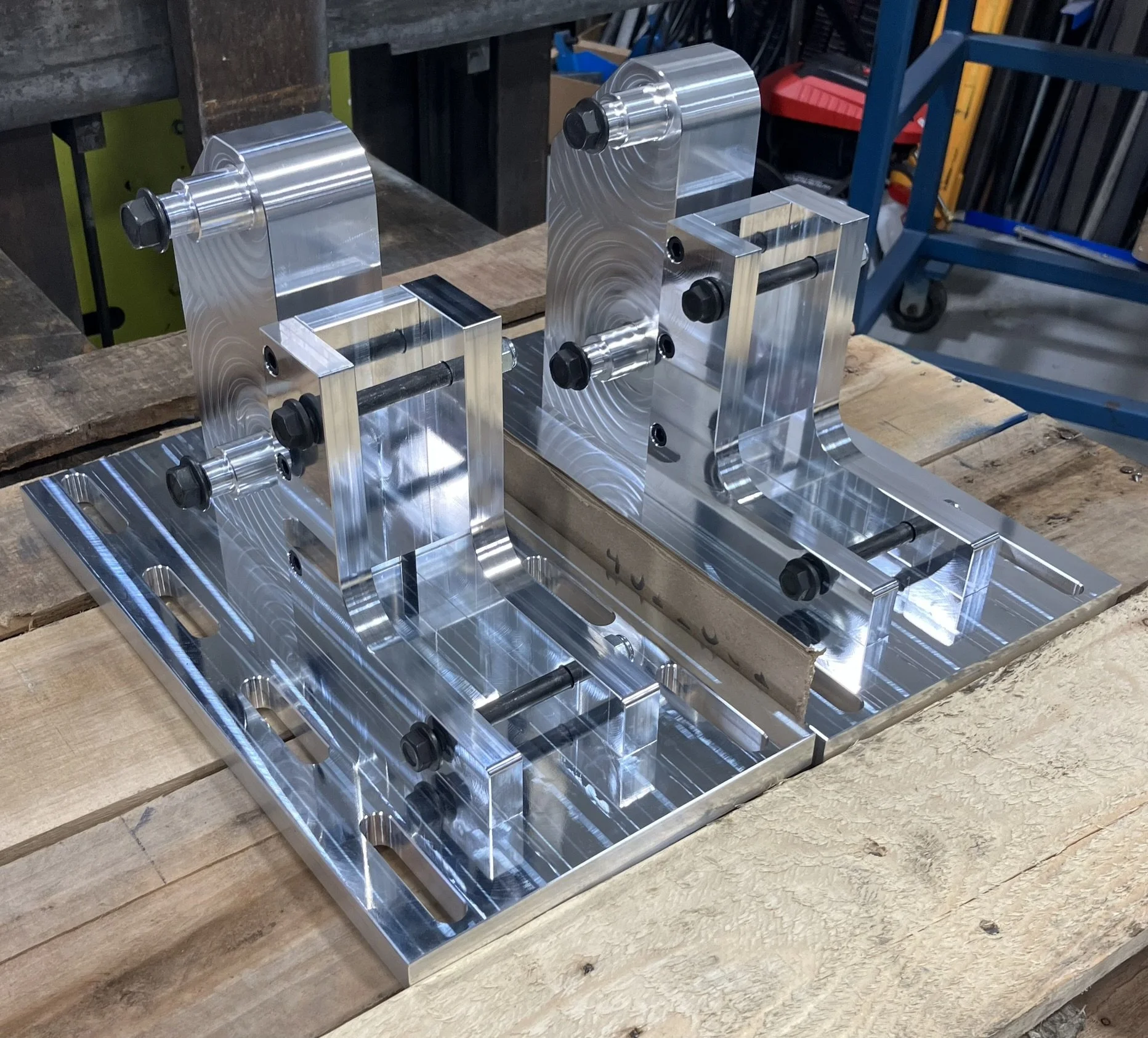

Holding | Environmental Fixtures

FEA/CAE Simulation

Rapid Prototyping

Design & Engineering Solutions

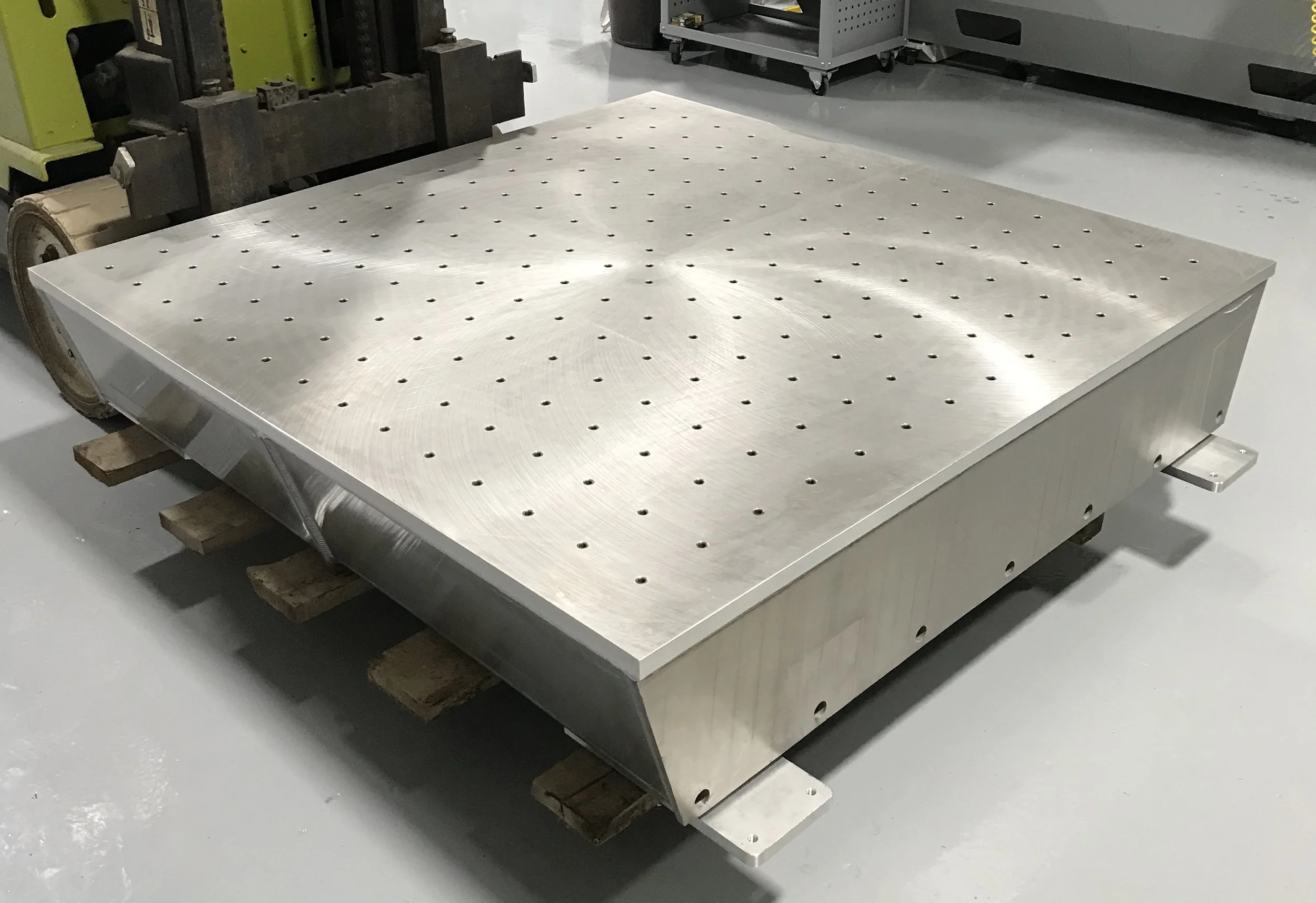

Vibration | Shock NVH Fixtures

Testing Equipment

Static | Dynamic Load Fixtures

Custom Fabrication & Welding

Trusted by

Big Brands

This will be about OEM brands.

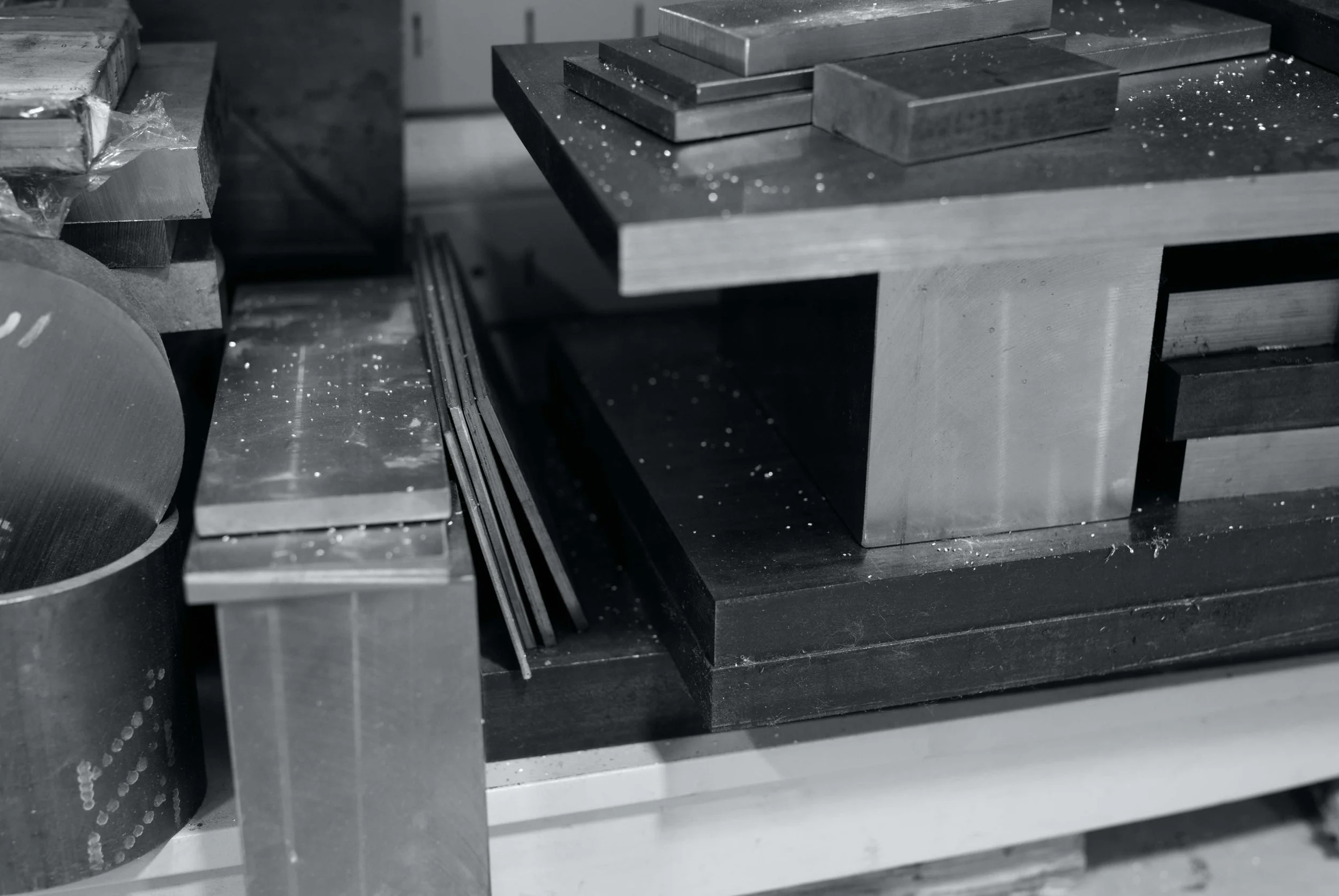

Fabrication

Fabrication

Fabrication