DME Fabrication began with a simple goal: build fixtures and test fixtures that don’t get in the way of the data. What started as a small prototyping shop has grown into a full-service partner trusted on launch-critical programs across the country without losing the responsiveness that got us here.

About DME Fabrication

What We Do

We design, build, and validate solutions that keep programs moving:

Automotive Test Fixtures: end-of-line functional, CMM & gauging, vibration & shock (NVH), holding/environmental, and static/dynamic load fixtures.

Custom Testing Equipment: static load frames, load forms, positioners, and general lab test systems with integrated controls and DAQ.

Precision Part Manufacturing: tight-tolerance components to support test rigs and pilot/production needs.

Looking for specifics? See our Capabilities and Testing Equipment pages.

Why COMPANIES Trust DME

Automotive-first expertise: deep familiarity with PPAP, validation gates, and lab protocols.

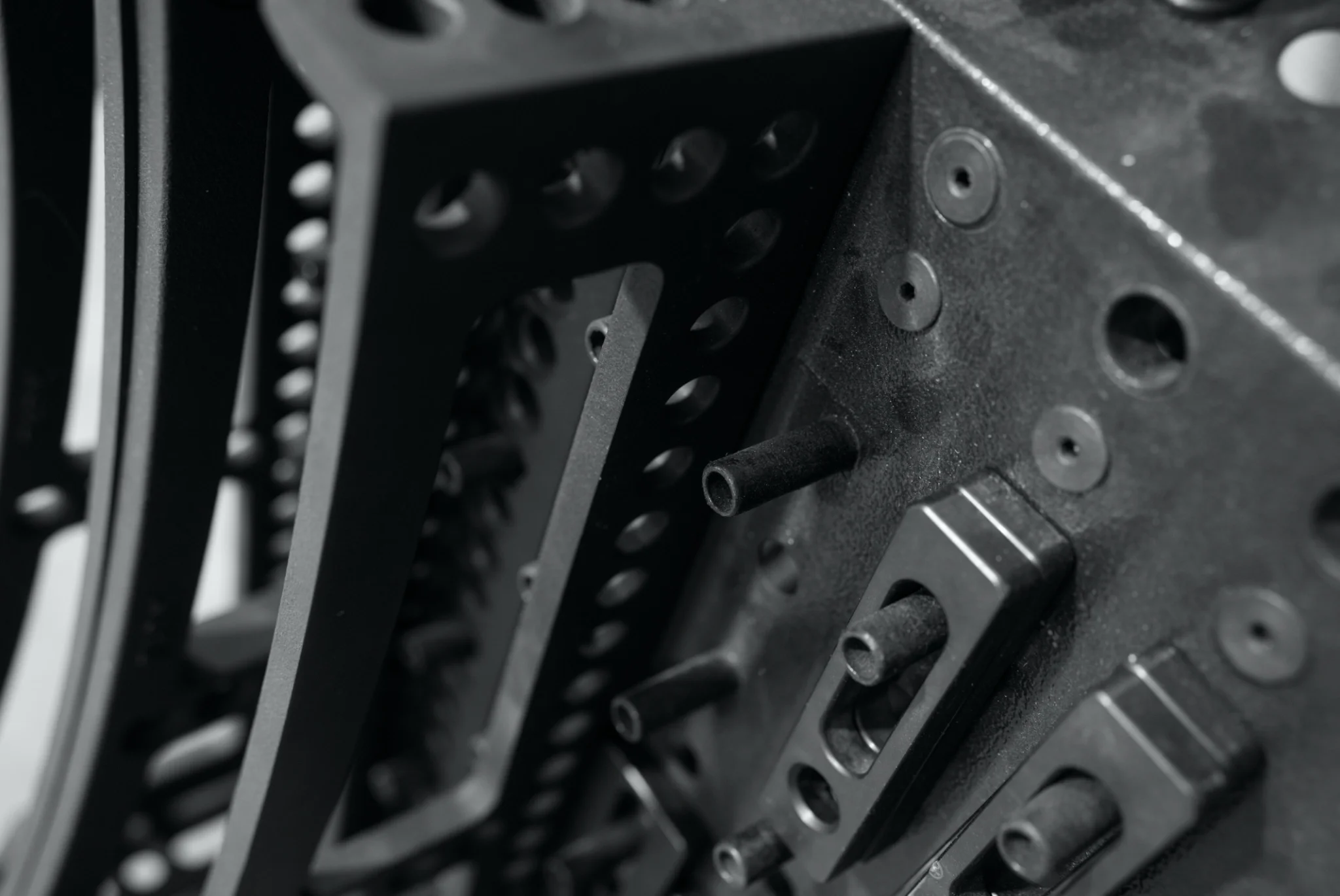

End-to-end control: in-house CAD/CAE, 5-axis CNC, welding/fab, industrial 3D printing, assembly, and CMM inspection.

Repeatability by design: tuned stiffness, clean load paths, low cross-axis response, and fixture dynamics engineered above test bands.

Confidential by default: NDAs, secure data handling, and white-label support for integrators and labs.

Nationwide support: rapid shipping, on-site install, and technician training across the U.S

Our Process

Discovery & Requirements – define loads, interfaces, frequency content, tolerances, and success criteria.

Engineering & Simulation – CAD/FEA, materials, and interfaces selected for stiffness and stability.

Manufacture & Assembly – 5-axis machining, precision welding/fab, and additive where it reduces mass or lead time.

Validation & Metrology – CMM verification, fit-up, and fixture characterization to confirm performance.

Install, Train & Support – on-site setup, documentation, and ongoing service.

Who We Serve

OEM & Tier-1 engineering teams (R&D, validation, production test)

Independent & in-house test labs

EV, ICE, chassis, driveline, body, electronics, and NVH groups

Facilities & Capabilities

Machining: 5-axis & 3-axis CNC, multi-axis turning, surface grinding

Fabrication: laser/plasma, TIG/MIG welding, stress relief, finishing

Additive: industrial-grade polymer/metal solutions for lightweighting and speed

Metrology: CMM, height gage, surface plates, certified gauge blocks

Controls/DAQ (as required): servo-hydraulic/electric actuation, sensors, safety interlocks

Quality & Compliance

Our quality-controlled workflows emphasize measurement integrity: calibrated metrology, gauge R&R where appropriate, revision control, and complete build documentation. If you operate to ISO or customer-specific specs, we align our process to your requirements.